During the 1990 Empuriabrava boogie, all the planes were stuck on the ground because of jet fuel contamination. Mike Fitzgerald, a young English skydiver on holidays in Spain, had just left his job as a chief mechanic in a big plane maintenance society in the north of England. He had a ten year experience and offered his help: he repaired all the planes ! Charly Baum decided to get back to Gap with Mike and offered him a job for a few months. Months turned into years and Mike worked as a mechanic for 3 years for MTA Aviation before starting his own company.

Icarius Aerotechnics was born in 1993 on the Gap-Tallard airfield and 2 years later, became a company owned by two people: Mike and his wife Corinne. Charly Baum then was their main client for the service of his planes, but now many DZs in Europe entrust their planes to Mike and his staff's expert hands. This workshop is competent in many fields and its success comes as much from the quality of the plane servicing as from its various specialisations...

The workshop and its approval

First of all, a company such as Icarius Aerotechnics cannot exist

without an approval given under certain conditions by the general

aviation authority (DGAC in France, FAA in the USA). There must be a

workshop, facilities satisfying standards and special technical

capabilities authorising a given type of service. The DGAC regularly

makes strict controls in order to validate the approval. The company

is then officially declared as an aeronautics maintenance factory and

its field of activities is defined by the competence of the people

working there. The turboprop plane (Twin-otter, Pilatus, Casa...) is

the king of the Icarius workshop. Most clients belong to the

skydiving community.

The 10 people staff can work on anything from basic servicing to the

total rebuilding of a Porter.

|

A decorations' history. The first original painting on a Porter appeared in 1987:

it was on the famous Turbo Mingo which was then based in

Deland, Florida, with its huge painted pink flamingo. The

idea was followed by many and the plane is still used for

skydiving over several European DZs. In 1991, Gap's Bravo

Sierra was the first French Porter to come out of Icarius

Aerotechnics workshops with an original painting: Europe's

stars on a navy blue background. The latest painting is on

the Annemasse Porter following an original idea by Fabienne

Prin, an achievement of which the plane owners and Icarius

Aerotechnics are very proud. |

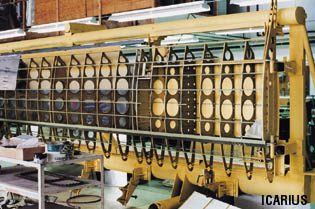

For the regular Porter servicing, a program has to be filed with the DGAC and approved. This program takes into account the manufacturer's standards and also the specific skydiving use. There are controls every 100 hours, every year, every 3 500 hours and every 14 years for a general review. During the latter, a total "face lift" of the plane can be made by Icarius Aerotechnics.

Painting the Porters

Icarius takes down, controls, strips and paints all the parts and then rebuilds the plane! This company can be considered as a pioneer of these special decorations. Says Corinne Fitzgerald: "A new painting is a big adventure for a DZ since it is its trademark and it is made to last." Most of the designs come from Fabienne Prin's fertile imagination but each DZ can of course choose its own colours. The last baby out of the Icarius workshop came from the USA and gives a good example of Mike and Corinne Fitzgerald's company's know how. On its arrival in France, it was a wreck, much to the dismay of its new owner !

The workshop's speciality

2 500, that is the average number of hours needed for the mechanics to get a broken-down Porter up and about! Once the shell is bought and brought back to the workshop, the staff gets busy bringing it back to life. A complete servicing and often, fuselage modifications (nose change for a new P&W motor, door change) are needed.

The owner then has a varied choice of interior and outer lay-outs: fuselage and cockpit colours, specific installations for skydiving (step, videoman handle...) and flight instruments. Just imagine the expression on the face of the happy owner of a Porter, who has bought a wreck, when he discovers his plane as good as new and with revolutionary colours !

|

Pilatus review 3 types of Porters - P- PC6 B1H2 : A20 turbine with a maximum

take-off weight of 2 200 kgs, authorised for 9 skydivers Production Porters for

skydiving Airframe : Pilatus Motor : Aztazou- Pratt & Whitney PT6 A20-A27 - Propeller : Hartzell 3 and 4 blades |

Not only does the Icarius staff make wonders when rehabilitating these planes but it also keeps track of them during their life time. A very strict technical follow-up is put in place. Indeed, each plane is different and the mechanics know them perfectly well. If a pilot faces a problem, he immediately tells Mike and his staff who decide whether the plane can fly again. Most of the time, Icarius travels to the corresponding DZ but the plane may also have to fly back to the workshop in the Alps.

Icarius' pluses

First of all, a privileged location in the French Alps where the French national skydiving teams train. Moreover and most of all, a staff able to understand and to answer quickly to the needs of skydivers, and for a good reason: Mike and Michel Vidal, one of the mechanics, both are pilots for skydiving activities and skydivers. Corinne is not outdone with her long past as a competitor, she is very well acquainted with skydiving problems, especially as regards the dropping of RW teams. Hence, the three of them are very involved in the skydiving world and, with the advice of the staff on the spot, problems are quickly resolved and planes are efficiently adapted to the needs. Moreover, judicious advice is given to the pilots in order to get the best performance possible from their machines during skydiving activities. The manufacturer gives its standards for the use of its planes and Icarius Aerotechnics adapts them to make specific adjustments for airdrops.

Indeed, neither the life of a Porter used for skydiving, nor the pilot's life are restful. This activity demands a very good technical follow-up and an optimised use of the machine's possibilities while keeping safety and comfort margins for the pilot, the machine and skydivers. "The advantage is that Icarius knows perfectly well the constraints due to the droppings, the large speed changes, the successive take-offs and landings. Everything is taken into account for the service which adds to the quality of the technical follow-up" says Sylvain Volpe, a pilot.

There are also a lot of constraints on the pilot's side. The average skydiver climbs to altitude six times a day and is tired at the end of the day. You can then imagine what a pilot endures when spending the day in his plane, often riding more than 15 round trips to altitude. Moreover, this is a repetitive work and the body is subject to as many pressure variations as the machine. Monotony is also a danger...

Add the sometimes unseemly requests of some pernickety skydivers, who may not know much about flying and you will have an idea of a pilot's life !

Conversions

In order to ease the pilot's work a little bit, Mike designed a few years ago a trim alarm which is one of the possible modifications on a Pilatus Porter. An alarm which could have prevented some accidents... It activates when the tail wheel leaves the ground, if the pilot forgets to put the trim back into flight position. The first plane equipped with this system flew in Gap but now most of the planes used for skydiving have it. Of course, everything that concerns a modification of the aircraft structure following the manufacturer's standards also requires an approval from the general aviation authority (DGAC). A request is then filed for each type of lay-out and for each plane on which the work is made. This applies to a step, a videoman handle, an alarm...

Another modification is the mounting of four-blade propellers. These propellers, designed in the USA and installed for the first time in France by Mike, bring an answer to the problem of noise pollution. They were tested during the RW worldcup in 1992 on one of Gap's Porters with a huge crowd invading the field. The change was obviously very positive even for the fiercest defenders of the alpine skies. Since then, other DZs have changed for four-blade propellers in order to reduce noise pollution.

Good flights...

A Porter is the ideal plane for dropping skydivers over our European DZs. There is no comparison however with the big planes usually used in the USA, the size of their fields being extraordinary large when compared to ours! The Porter still has a bright future ahead and Icarius Aerotechnics competence ensures a good life span with optimum safety conditions.

|

Field of activities: Pilatus Porter specialist, 23 Porters serviced in France, Spain, Germany, Italy, Switzerland and England. Particularities: reconstruction, motor changes (from pistons to turboprops) - Garett to Pratt & Whitney modification Elans : General servicing workshop for Pratt & Whitney

motors

Aéropole - 05130 Tallard Tél. (33) 4 92 54 16 23 Fax. (33) 4 92 54 16 22 |